Sciaky will exhibit EBAM machines during Formnext 2022

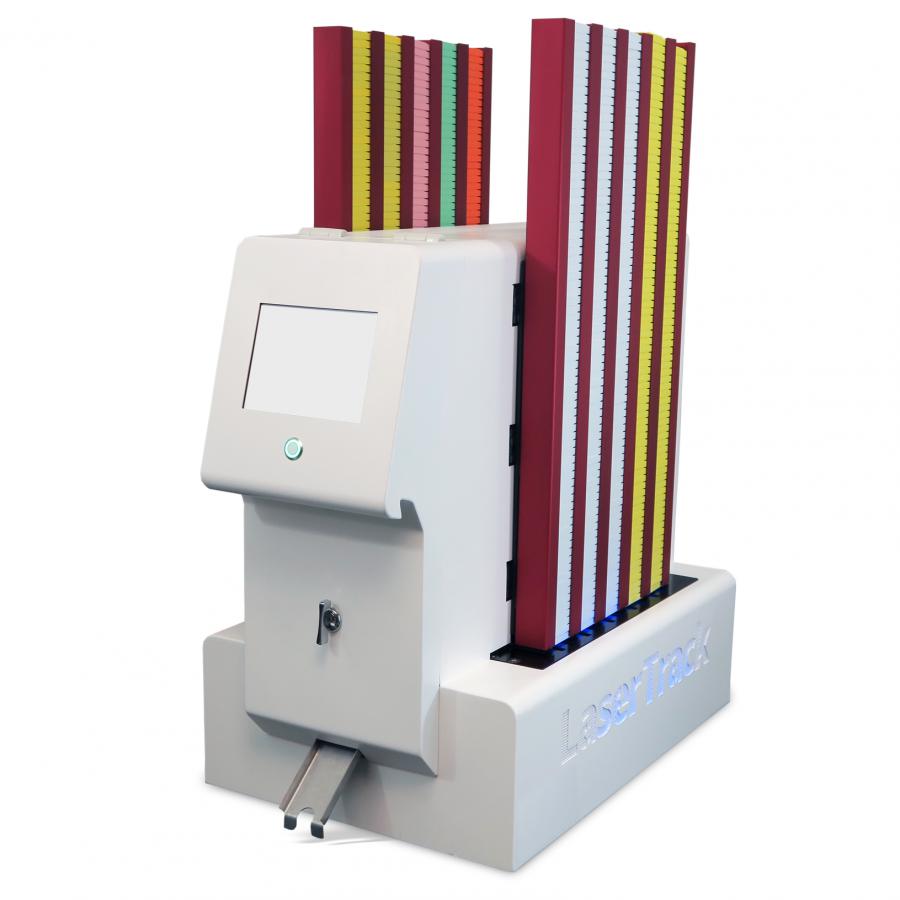

Sciaky, Inc. It has announced that it will be exhibiting aerospace components and refractory-metal test articles at Formnext These products were manufactured using its Electron Beam Additive Manufacturing machines.

The company will also discuss its Electron Beam Welding capabilities in Frankfurt.

Sciaky claims that its machines can deposit titanium at a record rate of 40lb/hr. The company’s Global Sales Team will be present to showcase Sciaky’s latest innovations, explain the process and design ideals behind EBAM and EBW, and to assist in implementing either (or both) to an application.

Sciaky’s Global Sales Manager John O’Hara will present on the machines capacity to switch between EBAM and EBW modes, which the company claims will allow customers to accomplish multiple production steps with the same machine. The presentation will demonstrate how Sciaky’s customers have implemented this capability, and the design considerations behind the usage of both EBAM and EBW.

“We are happy to be at Formnext for another year,” said Scott Phillips, President and CEO of Sciaky, Inc. “We’ve seen EBAM producing parts both bigger and faster year-over-year, all while improving quality, and we hope that manufacturers will build off of our innovations to save themselves both time and money making the biggest parts in their industry.”

Sciaky claims that their solution is the most widely-scalable metal additive manufacturing system in the industry. It has the ability to produce parts up to eight inches in length and can also be scaled to other sizes. Sciaky claims that EBAM is the fastest metal additive manufacturing process, with a gross deposition rate of seven to 40 lbs per hour.

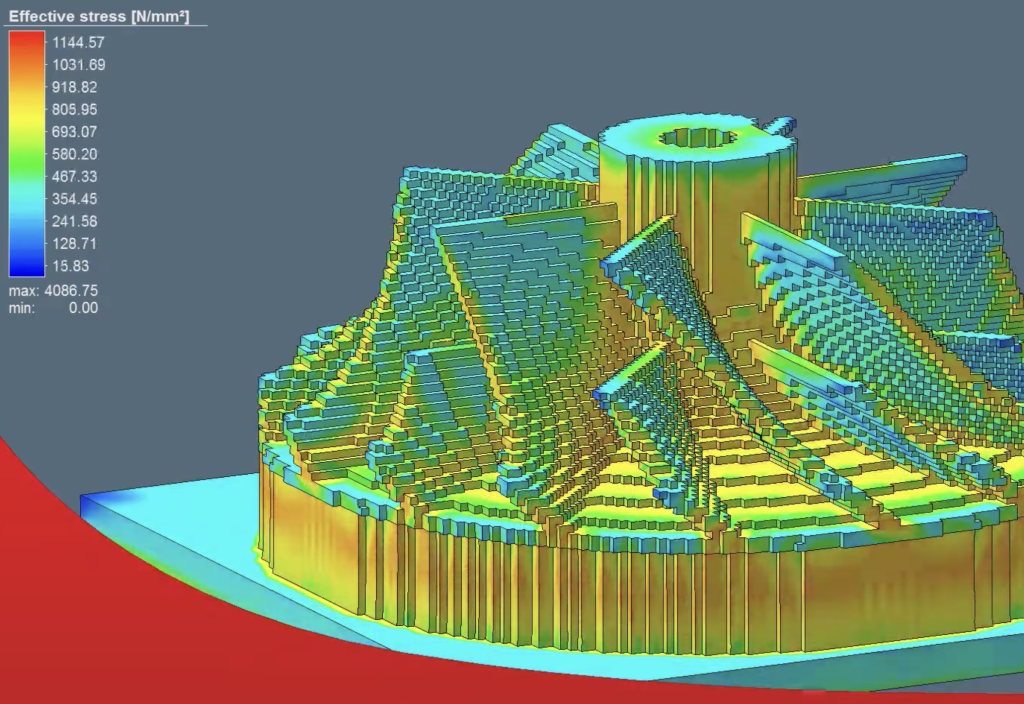

Sciaky’s EBAM technology uses IRISS – the Interlayer Real-time Imaging and Sensing System – which the company says is the only real-time adaptive control system in the metal 3D printing market that can sense and digitally self-adjust metal deposition with precision and repeatability.

The closed-loop control is the key reason for the company’s EBAM process delivering consistent part geometry, mechanical properties, microstructure, and metal chemistry from the first part to the last, according to the company.

Sciaky will present on the TCT Introducing Stage at Formnext on Wednesday, November 16, at 12:00pm CET.

Do you want to talk? Join the conversation on the Additive Manufacturing Global Community Discord.

Gain 3D printing insights from Boeing, Jack Wolfskin and more at the TCT Conference @ Formnext. Get your pass here.

Get your FREE print subscription to TCT Magazine.

https://www.tctmagazine.com/api/content/d3ed91f6-61dd-11ed-9ff2-12274efc5439/