Recycle 3D Printer Filament with This Low-Value DIY Extruder

FDM (fused-deposition modeling) 3D printers use plastic. And whereas the ensuing waste isn’t even a drop within the world bucket and pales compared to conventional fabrication strategies, many hobbyists are keen to cut back their contribution to the issue of plastic waste. Happily, FDM 3D printers use filament product of thermoplastic and it’s potential to reuse that — and family waste plastic — for brand new print jobs. To make that course of reasonably priced, Thomas (AKA Tin Foil Hat) designed this DIY extruder.

Resin 3D printers, together with the MSLA (masked stereolithography) fashions which can be widespread on the buyer market, make the most of photopolymer resin that undergoes a chemical change (photopolymerization) when uncovered to UV mild. There isn’t any strategy to reverse that chemical response, so the fabric in an MSLA-printed half can’t be used once more.

However FDM printers are totally different, as a result of they use filament product of thermoplastic. When uncovered to warmth, the filament melts. When it cools, it solidifies. No chemical response happens, so this course of is repeatable and that’s precisely why Tin Foil Hat’s DIY extruder works.

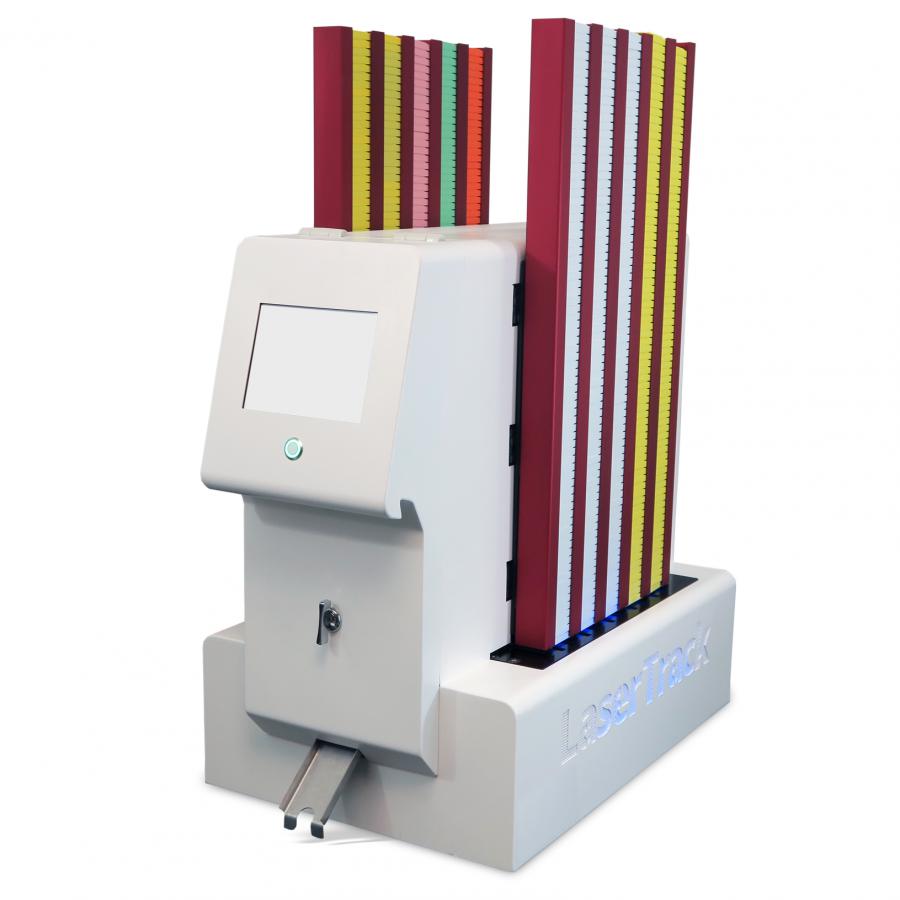

Step one is to shred and grind appropriate thermoplastic waste down into small fragments, performed with a separate machine. That waste can come from failed prints, elements that aren’t helpful anymore, or rubbish. It simply must be clear and of an identical sort. Some thermoplastics are impractical for 3D printing, however there may be info obtainable on-line about each materials you’re prone to come throughout. The shredded plastic feeds from a hopper into an auger that pushes right into a scorching finish, just like the one in your 3D printer. The extruded plastic can then be drawn by way of a nozzle and spooled to be used in a 3D printer.

This machine works so much like a 3D printer, however with solely an “E” axis and hopper/auger as a substitute of a standard direct drive or Bowden extruder. It wants a motor with velocity controller to drive the auger and two units of temperature management elements. The latter encompass PID temperature controllers, thermocouples, and solid-state relays. Collectively, they management the warmers that soften thermoplastic because it enters into the recent finish, sustaining the right temperature to make sure constant extrusion with out burning.

These elements, together with the ability provide and mechanical elements, all mount onto a body product of welded metal tube. As Tin Foil Hat factors out, welding could sound intimidating to the uninitiated, however the fundamentals of MIG welding are simple to study.

The ensuing machine will allow you to make the most of thermoplastic that may seemingly find yourself in a landfill in any other case. Nevertheless, it’s price noting that the filament produced by this machine shall be inconsistent — each in geometry and composition. It would nonetheless work, however gained’t be nearly as good as new filament from a manufacturing unit.