Q5D launches CY1000 CNC Additive Manufacturing Robotic Cell

Wire harness automation equipment manufacturer Q5D Has announced the launch its CY1000 5 axis CNC additive Manufacturing (AM) robot cell.

The CY1000 is designed to automate the electrical connections of increasingly complex products.

Per Q5D, traditional wiring harnesses are heavy, ‘space-hungry’, and costly, whereas its CY1000 product is said to add components, connections, and conductors automatically, economically and securely into metal, ceramic and polymer products or components.

Q5D’s CY1000 AM robotic cells, Q5D claims, eliminate the need for separate wiring harnesses that are prone to faults. They also claim this process will improve reliability, reduce design constraints and cut costs. According to Q5D’s self-contained CY1000 robotic cell, it can be located with the final assembly and eliminate the expensive transportation of heavy wiring harnesses.

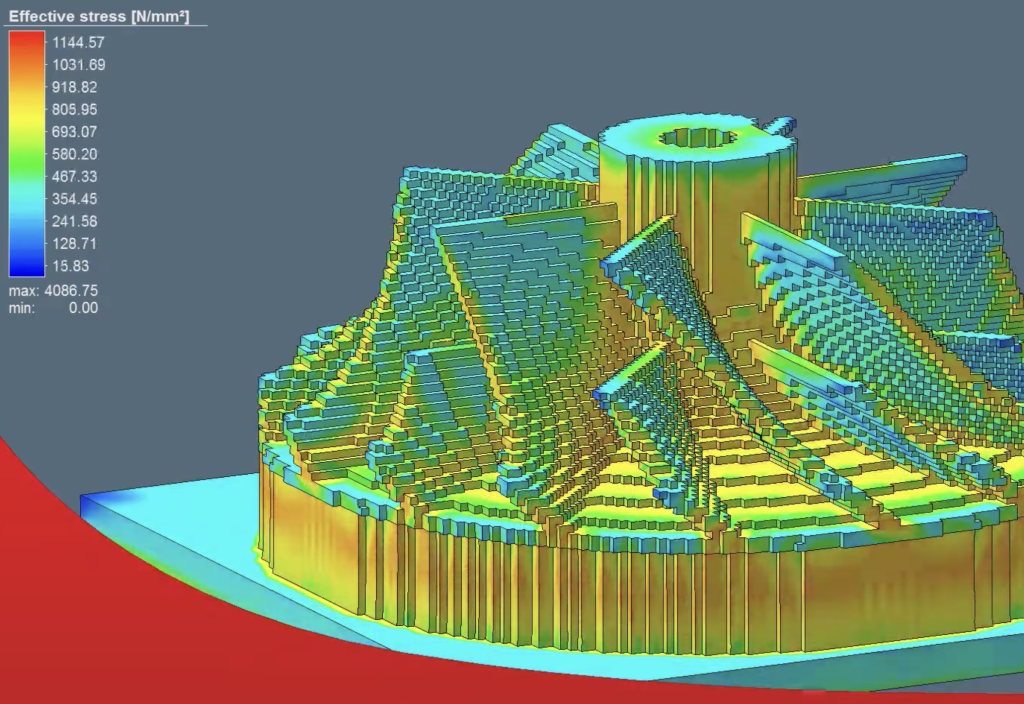

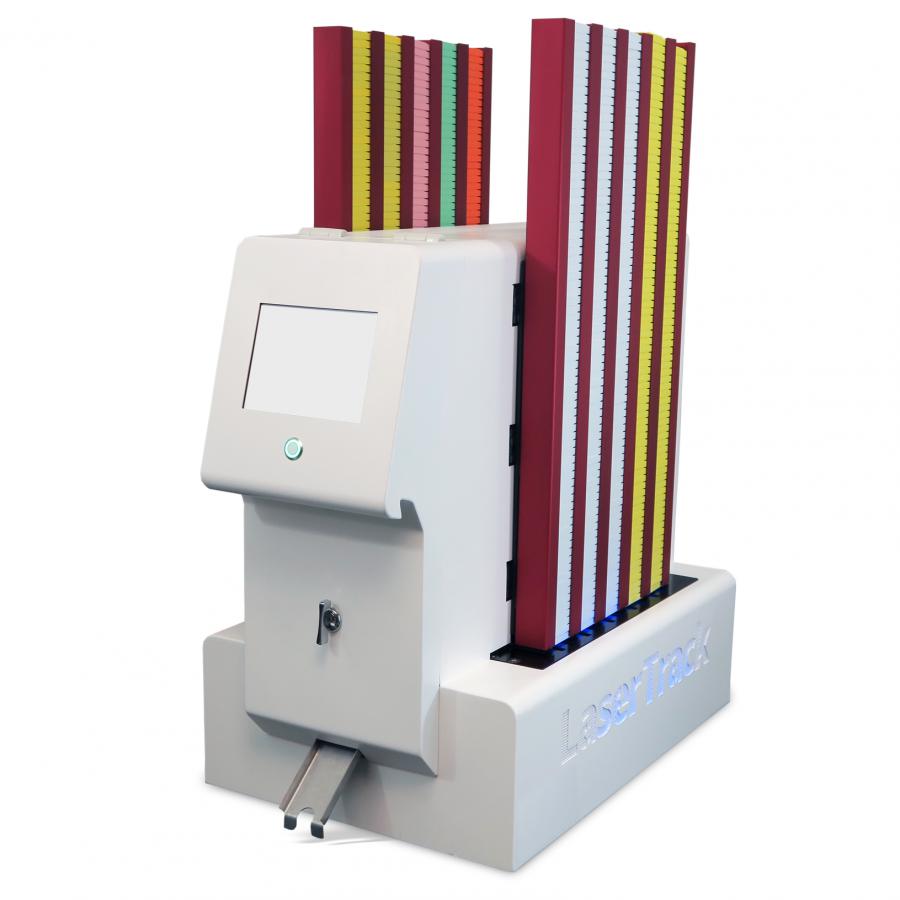

The CY1000, with its robust steel frame gantry, is ideal for standalone use or easy integration into a process line. It offers full-depth robotic loading. Each machine is capable of extruding a variety polymers from Nylon, PEEK, and Kydex using a range of specialised tools. Electrical connectors and parts can be selected and placed. The CY1000 is also capable of creating 3D shapes, and connecting them to components that have precision integrated wiring.

CY1000 users can mould and stamp large components up to a diameter of 1m, or multiple smaller parts, before loading them into the cell. Siemens NX solutions for CAD/CAM allow the user to define electrical functions within the cell.

The CY1000’s external dimensions are 2300 mm wide x 2170 mm long x 2320 mm high, while its head and bed axes move at up to 70 revolutions per minute. Q5D customizes each CY1000 to the intended application. They also supply polymer and wire end effectors. Wiring can be made of bare copper or insulated, with a maximum diameter of 3mm. The company says that conductive ink end-effectors will become available this year.

“Almost all wiring harnesses in this $200B+ market are made by hand at present,” commented Q5D CEO Steven Bennington. “With the demand for wiring driven by electrification, the internet of things, and net zero, automation is the only way to keep pace.”