OSU students learn to use the state’s first 3D printer for construction

Ben DiMarco works as a researcher for the Center for Design and Manufacturing Excellence at Ohio State.

DiMarco noted that construction workers are on average 48 years old. This means a new generation of workforce development will be needed. 3D printed concrete or automated construction has many uses in the construction industry.

He said that structures could be completed faster and with less labor with additive manufacturing.

“It’s meant to augment or supplement current building technologies. Right, so we have this deficit of housing and available housing, and if we can automate it and bring more structures to life more quickly, I think that’s going to help bring that deficit down,” he said.

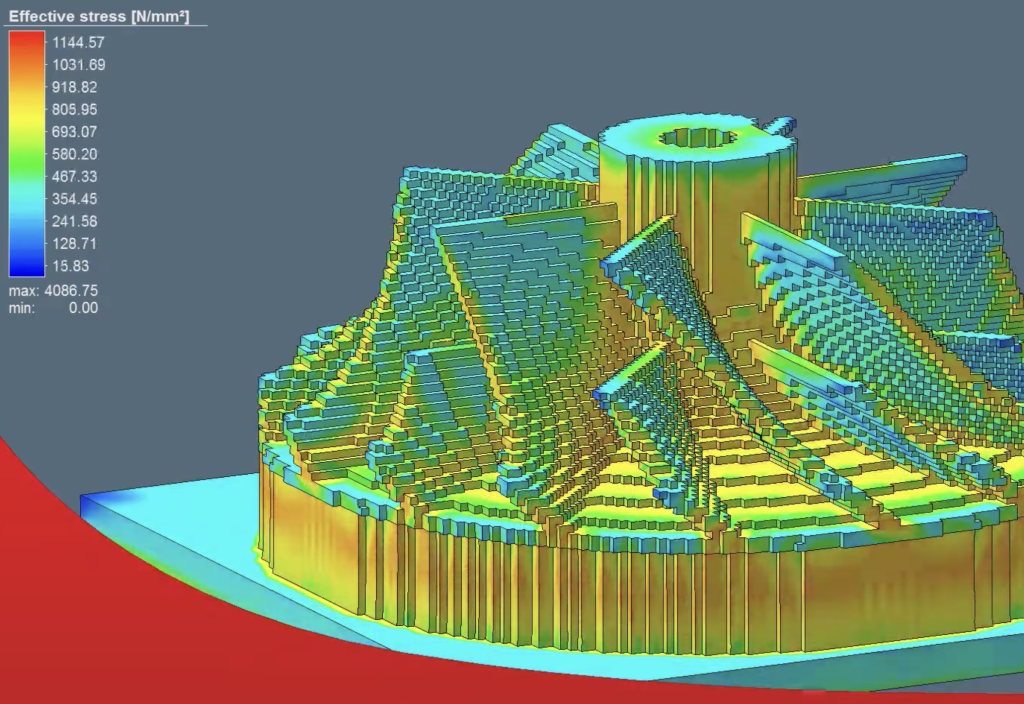

Ohio State’s CDME is working with Youngstown-based Pantheon3D to accelerate growth in the residential and commercial construction 3D printing industry.

“They can be involved in the early stages of designing a structure, they can be involved in the middle stages in planning or engineering with civil, mechanical, industrial backgrounds,” DiMarco said.

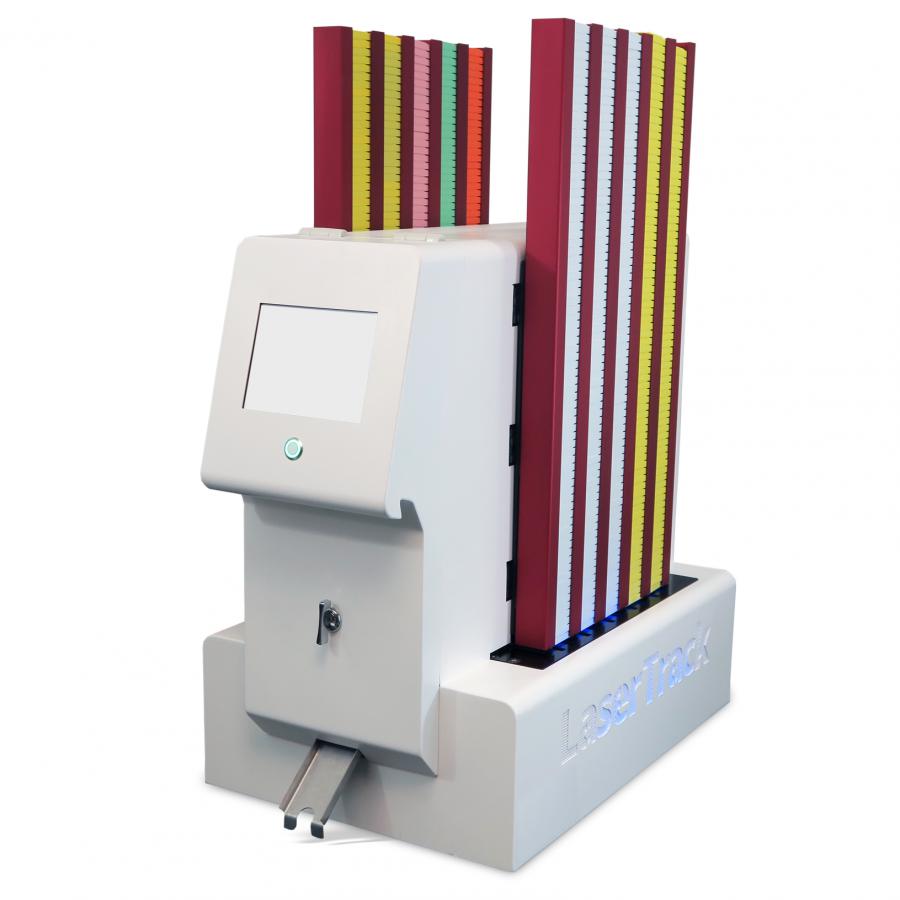

This concrete printer is one of only a few dozen in the world.

Justin Levy from California, who moved to Ohio to learn about this new technology, was greeted by the sight.

“I’ve been interested in additive for five, six years now and had my own printers at home, printing out of my parents’ kitchen. So it’s just a dream to be able to be here and be able to use industry machines as a first-year student here,” Levy said.

DiMarco stated that the CDME program offers a wonderful opportunity to supplement your coursework with hands-on training of 15 hours per week.

His students, he believes, will be able to start their careers on the first day of employment.

“When they’re working at our research center, they’re working with real customers with real project dollars and real deadlines,” DiMarco said. “And I think that’s important, especially in the academic setting or hey this isn’t for a grade, it’s a real customer. I think that what you can takeaway is you can’t fake real.”