3D printing is expanding with new products

As additive manufacturing develops the capability to produce larger and larger parts, it’s important not to forget that the opposite is also true. Microscale additive printing, also known by micro 3D printing can produce complex, highly detailed parts with very small dimensions. This sector of 3D printing has been around for many years. However, it is still growing as more intricate microscale parts are made for consumer products and aerospace.

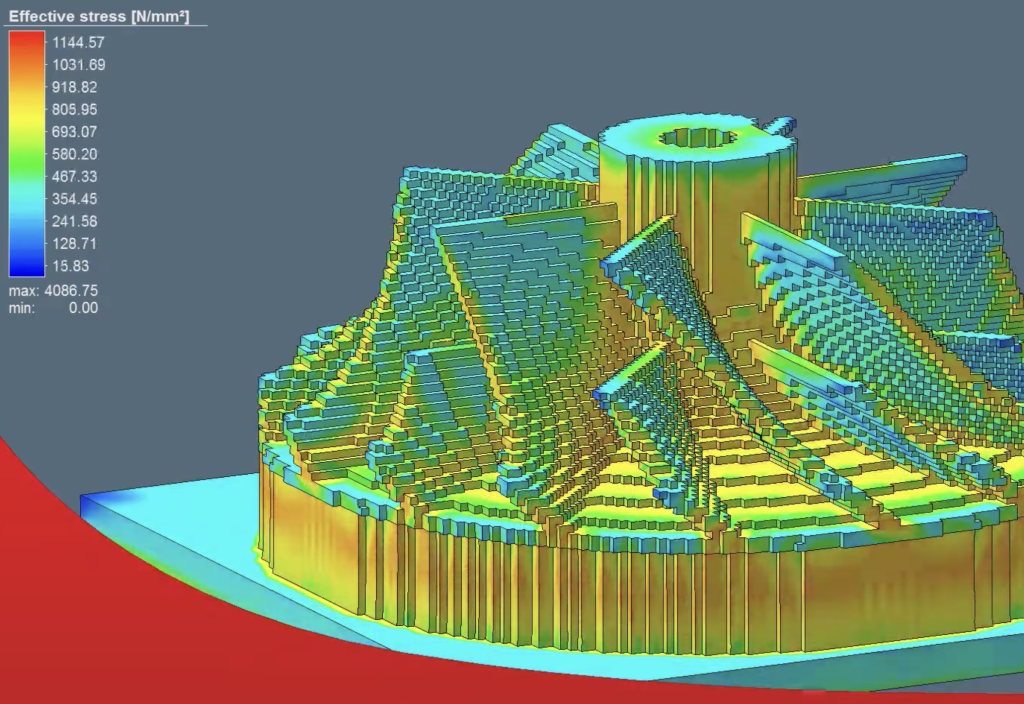

Since their arrival in the market, companies like Nanoscribe and Nano Dimension have been continuously improving their micro 3D printing technology. Boston Micro Fabrication (BMF), a leading microscale additive manufacturing firm, recently introduced its microArch S350, its latest addition to its line-up of industrial-grade microprecision 3D printers.

The microArch S350 utilizes BMF’s patented Projection Micro Stereolithography (PµSL) technology, which cures layers of photopolymer resin using a flash of UV light. The new printer can produce parts with resolutions of 25 µm with the highest throughput in the company’s current portfolio.

|

Image courtesy Boston Micro Fabrication

|

| The microArch S350 from Boston Micro Fabrication has the highest throughput in the company’s portfolio. |

“BMF has become the industry leader for printing small and micro-sized parts requiring high resolution, accuracy, and precision in the 2- and 10-µm resolution spaces. Now, we’re bringing that experience to an even wider range of end-use applications at the 25-µm level,” said John Kawola, CEO of BMF. “While this printer is geared more toward industrial customers that need faster throughput, greater volume, and more automation, the result is still best-in-class part quality compared to other DLP platforms, and we cannot wait to see what our customers accomplish with it.”

BMF also announced that two new 3D-printing resins were launched: BMFMED powered by 3D Systems, and Loctite 3D 3D 3555.

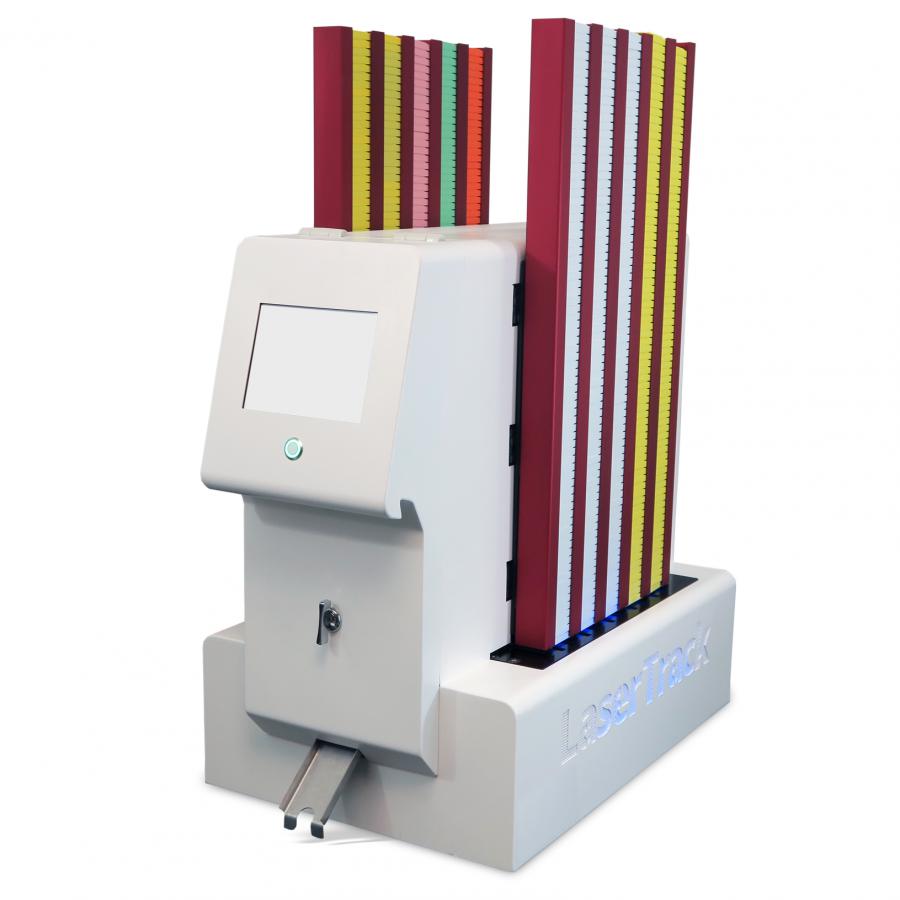

The launch of ChromaScan by Chromatic 3D Materials, a Minneapolis-based 3D printing technology provider, was announced. This software allows 3D printing on non-planar surfaces. ChromaScan allows users to print flexible and durable materials directly onto any type of substrate. This includes metals, plastics, and textiles. According to the company, ChromaScan’s technology eliminates the need for post-processing and assembly with adhesives and stitching.

|

Image courtesy of Chromatic 3D materials

|

| ChromaScan software makes it easy to remove some of the post-processing work required for 3D-printed parts. |

“Hyperbolic print paths are challenging for existing technologies. ChromaScan can easily adapt a flat print path to printing on 3D surfaces. This opens up a world of design possibilities, as well as more streamlined, cost-effective, and sustainable manufacturing for our customers,” said CEO Dr. Cora Leibig.

ChromaScan is a scanning of an object on the print surface. The object is then manipulated along the print path until it conforms to the surface. It is ideal for automotive, apparel, footwear, and other industrial applications.

It is complicated to print 3D objects, as demonstrated by developments like the ChromaScan or the microArch s350. 3D printing will be able to adapt to new technologies as they emerge.

https://www.plasticstoday.com/3d-printing/new-products-push-limits-3d-printing