New facility turns exhausting plastics into 3D printer feedstock

Renew IT Founder and CEO James Lancaster and UNSW SMaRT Centre Founder and Director, Professor Veena Sahajwalla. Picture: UNSW

A collaboration between UNSW Sydney’s Centre for Sustainable Supplies Analysis & Know-how (SMaRT) and Renew IT has begun turning discarded exhausting plastics into 3D printer feedstock.

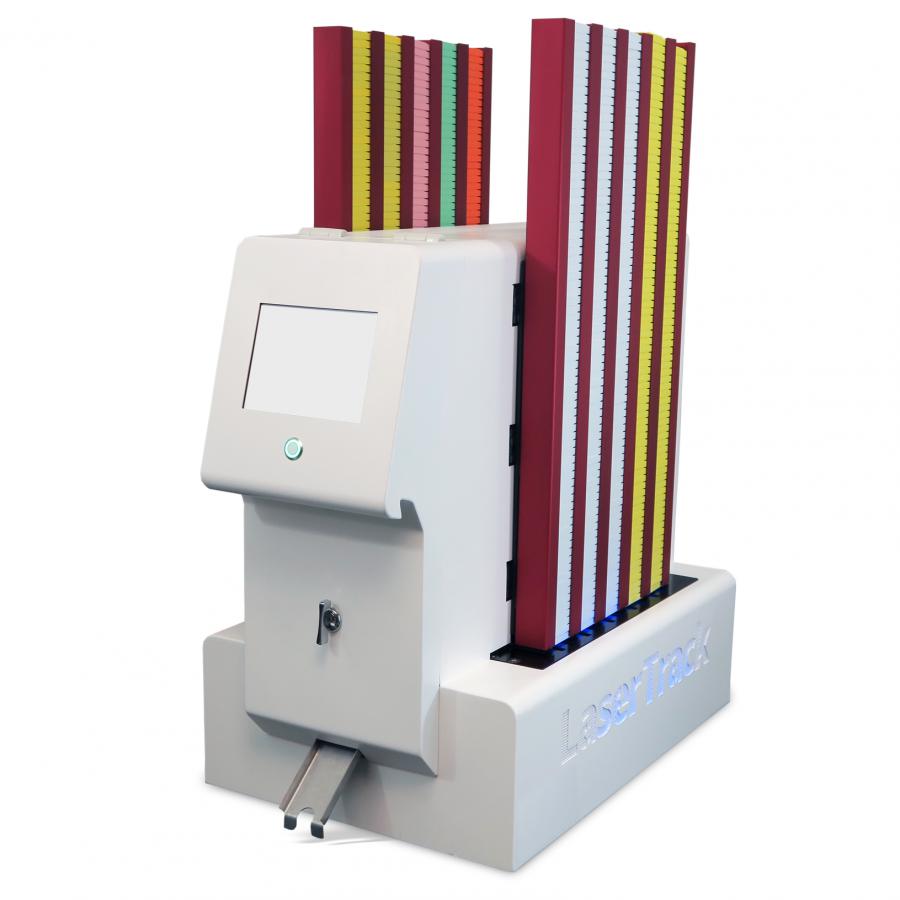

A UNSW-invented Plastics Filament MICROfactorie™ Know-how module has been put in on the IT asset administration firm, Renew IT’s Sydney warehouse in Lane Cove, Sydney.

UNSW SMaRT Centre founder and director, professor Veena Sahajwalla, mentioned the system is a sustainable waste, recycling, and manufacturing answer.

“… It’s a sustainable waste, recycling, and manufacturing answer. We’re turning the exhausting plastics present in all fashionable digital {hardware} however not topic to traditional recycling strategies into feedstock for a booming sector,” mentioned Sahajwalla.

“Filament is nearly totally imported to Australia and made out of petrochemicals, so with the ability to regionally make it from used plastics additionally reduces the environmental impacts from international freight. 3D printing is an excellent expertise having fun with fast uptake however the tragedy is till now 3D printing has been reliant on virgin plastics.”

UNSW vice-president of Societal Affect, Fairness and Engagement, professor Verity Firth, mentioned UNSW’s partnership with Renew IT has the potential to create real, large-scale change.

“The mix of Prof. Sahajwalla’s pioneering science and Renew IT’s industrial experience and monetary dedication can speed up real change. This trade partnership is an beautiful instance of UNSW’s dedication to societal influence.”

UNSW Sydney can also be growing a Societal Affect Framework to maximise progress in environmental sustainability and resilience, social cohesion, well being, wellbeing, and financial prosperity.

Renew IT CEO and founder, James Lancaster, mentioned, “This enterprise addresses two depraved points.”

“Not solely does it scale back virgin plastic manufacturing by creating 3D printing filament from waste objects, but it surely additionally stops exhausting plastic ending up in landfill,” mentioned Lancaster.

“If 3D printing feedstock could be competitively produced by recycling plastic, we shouldn’t be producing it with virgin supplies.

“By recovering high-quality plastics from e-waste for re-manufacturing, we will help organisations decrease their Scope 3 emissions and enhance native manufacturing.”