ASTM Leads New Partnership to Strengthen US Submarine Provide Chains

International requirements group ASTM Worldwide has introduced a brand new collaboration with shipbuilder Austal USA and US protection non-profit BlueForge Alliance.

The strategic partnership seeks to advance the US Navy’s additive manufacturing capabilities and strengthen future provide chains for home submarine manufacturing. All three organizations will work to create a strong and safe manufacturing system that helps new elements and through-life spares manufacturing.

By leveraging ASTM’s widely known business requirements, the challenge will reportedly drive greatest practices for technical qualification and provider activation. Notably, it will guarantee compliance with the Navy’s stringent manufacturing qualification necessities, whereas advancing innovation in 3D printing for protection purposes.

“This partnership demonstrates the energy of mixing worldwide requirements with rigorous Navy necessities to construct a strong and certified AM provide chain,” commented Dr Mohsen Seifi, ASTM Worldwide’s Vice President of International Superior Manufacturing Packages.

He referred to as the collaboration “an thrilling step ahead” which can speed up the development and adoption of additive manufacturing within the US protection sector.

New partnership to boost the US Navy’s AM capabilities

Heightened international battle, sustainability challenges, and threats to worldwide delivery have prompted the US Division of Protection (DoD) to develop its adoption of additive manufacturing. By enhancing its 3D printing capabilities, the US navy goals to create strong, aggressive, and sustainable home provide chains for mission-critical parts.

This new ASTM-led partnership hopes to play a key position in addressing this demand. It would see the requirements skilled’s Additive Manufacturing Heart of Excellence (AM CoE) work alongside Austal USA and BlueForge Alliance to develop a complete provider activation course of.

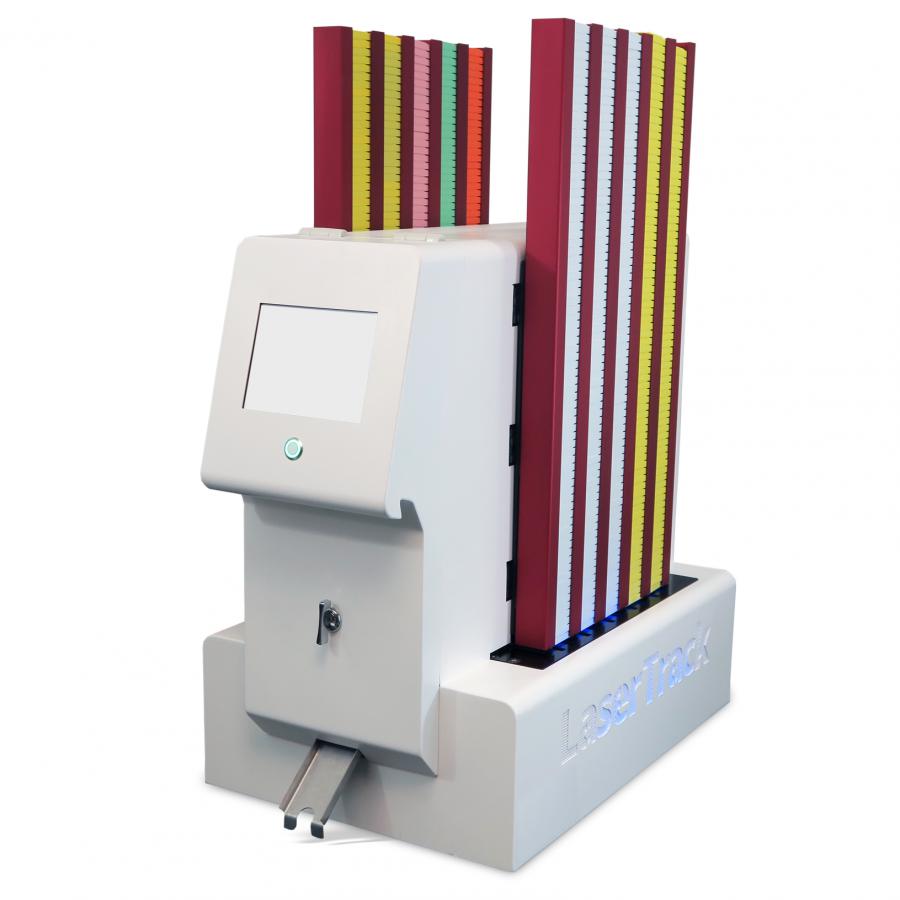

The AM CoE will present experience in additive manufacturing, requirements improvement, certification, and coaching. ASTM is about to supply workshops, audits, and steady enchancment processes to make sure suppliers are certified to fulfill the Navy’s wants.

A phased strategy will probably be utilized to onboard suppliers by way of the Navy’s regulatory framework. Considerably, it’ll emphasize the upskilling of current workforces to fulfill strict additive manufacturing necessities and demanding timelines.

This information follows the launch of ASTM’s Additive Manufacturing Certification Committee (AMCC) earlier this 12 months. Backed by over 25 3D printing finish customers, the AMCC seeks to attach key stakeholders throughout completely different industries. Members collaborate on audit standards for qualifying additive manufacturing provide chains based mostly on worldwide requirements and business greatest practices.

In line with ASTM, the brand new partnership with BlueForge and Austal aligns with AMCC initiatives by decreasing the burden on suppliers and unlocking larger scalability.

Dr Scott Kasen, Director of Know-how at Austal USA’s Superior Applied sciences division, views the collaboration as important to advancing the Navy’s adoption of “cutting-edge AM expertise to handle essential provide chain challenges.” He believes that growing a professional and compliant provide chain will make sure the Navy “stays forward in an evolving protection panorama.”

BlueForge is an skilled operator within the US Protection ecosystem, specializing in supporting the Navy’s industrial base initiatives. Since 2022, the non-profit integrator has secured roughly $1.3 billion from the Division of Protection to boost the Navy’s provide chain capabilities and capability. The funding has additionally gone in direction of workforce improvement, superior manufacturing applied sciences, and outsourcing initiatives.

Final month, the group acquired $951 million by way of the only supply Navy award. This financing will assist efforts to uplift the US Submarine Industrial Base, together with scaling additive manufacturing, robotics, and automation applied sciences.

How vital is that this information? Take 15 seconds to inform us, and be sure you click on submit!

3D printing secures US protection provide chains

The US Navy is main the adoption of additive manufacturing within the US navy, having acknowledged 3D printing as a key answer to the DoD’s provide chain wants.

Final month, it delivered a $12.5 million contract to Rocket engine producer Ursa Main to scale the manufacturing of 3D printed strong rocket motors (SRM).

The prototype challenge settlement (PPA), delivered with the Workplace of Strategic Capital (OSC), will see the corporate design, manufacture, and take a look at a brand new SRM prototype for missiles essential to nationwide safety. By 3D printing the SRMs, Ursa Main hopes to alleviate provide challenges which are stunting DoD efforts to restock US inventories and assist Ukraine and Israel’s ongoing struggle efforts.

Earlier this 12 months, it was introduced that the Navy was leveraging metallic and polymer 3D printers throughout the Rim of the Pacific (RIMPAC) navy train in Hawaii.

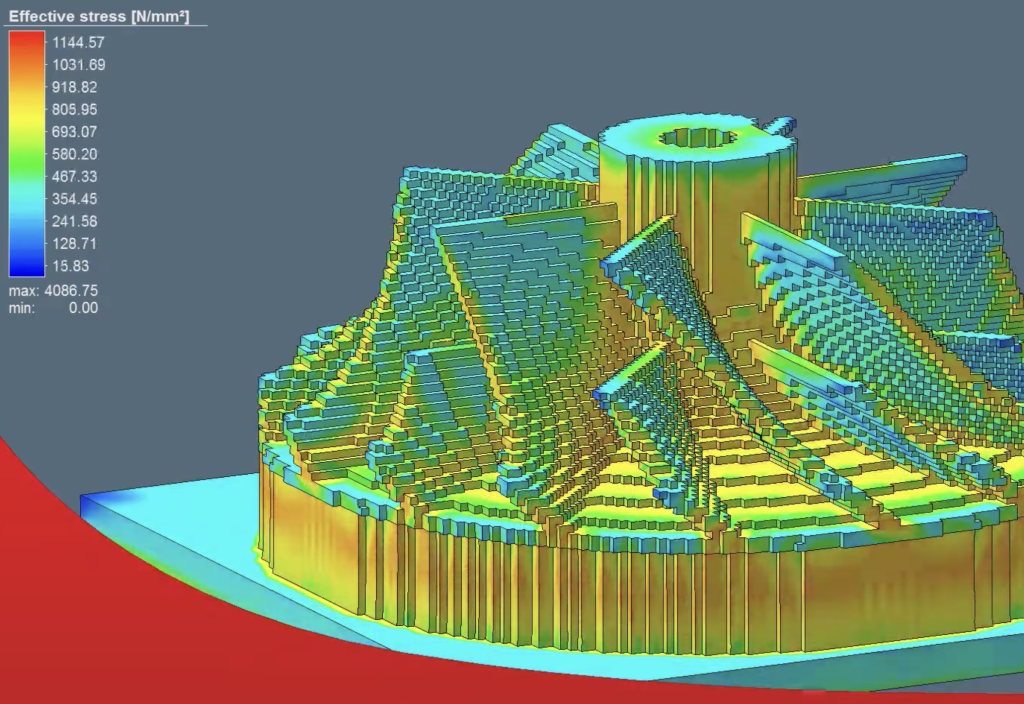

RIMPAC assessed the worth of SPEE3D’s XSPEE3D chilly spray 3D printer and Snowbird Applied sciences’ SAMM Tech hybrid DED manufacturing system for securing navy provide chains within the discipline. The trial sought to cut back the supply time of mission-critical elements from days to hours by way of a “cradle-to-grave” strategy.

Elsewhere, Australian 3D printer producer AML3D has provided a number of of its ARCEMY metallic 3D printers to assist the US Navy’s Submarine industrial base and advance its US ‘Scale-Up’ technique. This initiative seeks to instantly handle US DoD provide chain challenges, with a concentrate on US Navy submarines. In line with AML3D ‘Scale-Up’ delivered over AUD$12 million from orders in 2023 alone.

In Might 2024, Laser Welding Options (LWS), a element provider to the US Navy, ordered two AML3D ARCEMY Small Version 2600 3D printers. The deal, price AUD$0.70 million (US$0.46 million), has seen LWS lease the 3D printers to qualify ARCEMY Nickel Aluminum Bronze (NAB) parts for submarine purposes. This deal provides to the corporate’s current ARCEMY 2600 system, which it acquired in September 2023.

Nominations are actually open for the 2024 3D Printing Trade Awards.

What does the way forward for 3D printing maintain?

What near-term 3D printing tendencies have been highlighted by business specialists?

Subscribe to the 3D Printing Trade e-newsletter to maintain up with the most recent 3D printing information.

You can even observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture reveals a US Navy Virginia-class submarine. Photograph through the Naval Sea Techniques Command (NAVSEA).