Superior manufacturing revs up in Europe with 3D printing

3D printing is about to revolutionise European manufacturing, producing complicated, multilayered elements for every thing from toys and vehicles to wind generators and satellites.

By Anthony King

If 3D printing makes good on its promise, it would basically change the best way issues are manufactured. And it might additionally turn out to be everybody’s greatest buddy. Simply think about if for any damaged half in your family, you might merely make a brand new one with your property printer.

Because of advances made by an EU-funded analysis group, it’s now attainable to print superior components for motorbikes, vehicles, plane and even satellites utilizing totally different supplies and shapes whereas producing a lot much less waste. It’s even attainable to embed electrical conductors or optical fibres that may act as sensors.

Multilayered manufacturing

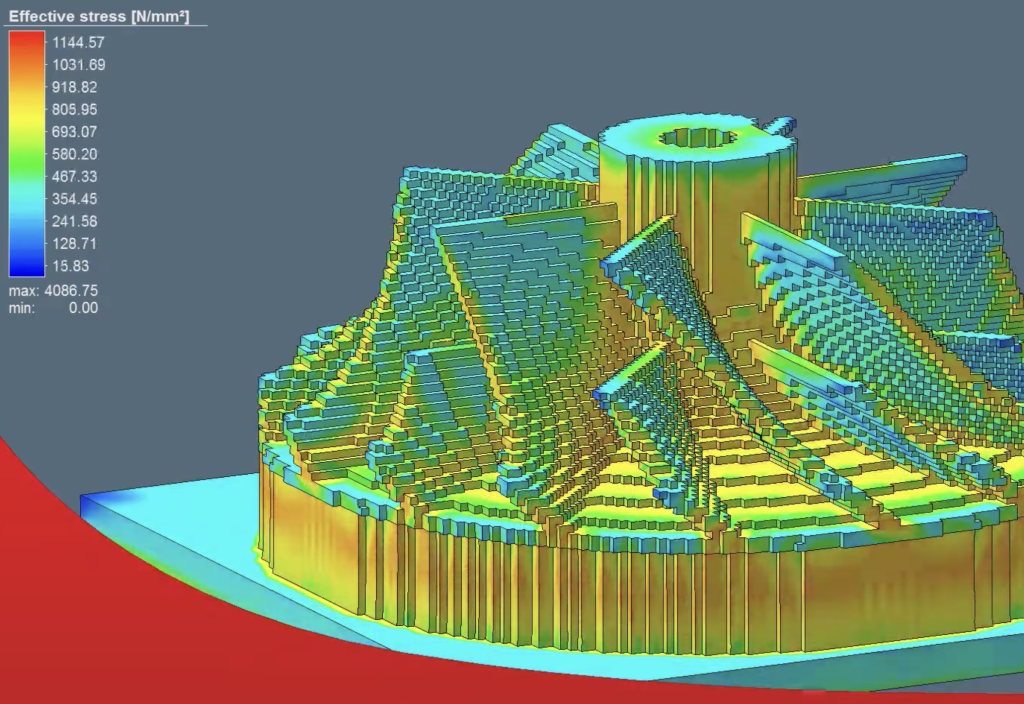

It is because 3D printing can enable components to be created layer by layer, making it simpler to seamlessly mix, for instance, metals, plastics, ceramics and even fibreoptics collectively, in a single half, in a single course of. This permits firms to make smarter components utilizing precisely the quantity of fabric wanted, thus decreasing waste to a minimal.

Rudolf Gradinger, a analysis engineer on the Austrian Institute of Know-how, is without doubt one of the researchers serving to to drive these developments ahead. He headed up a three-year multi-country analysis initiative referred to as MULTI-FUN that obtained funding from the EU to push the boundaries of 3D multi-material manufacturing.

The MULTI-FUN group, which labored collectively over three and a half years till December 2023, included researchers and industrial companions from throughout Europe (Austria, Belgium, Germany, Poland, Portugal, Spain, Switzerland, UK). Their focus was on creating revolutionary superior supplies prepared for market. The participation of 9 SMEs performed a key position in serving to to speed up market uptake.

Gradinger highlights the instance of an airplane half containing optical fibres. The researchers constructed up the half layer by layer utilizing aluminium and embedding optical fibres. This gave it “unattainable superpowers”.

‘The nerves in your arm imply you’ll be able to sense when your arm will get twisted,’ stated Gradinger. ‘These optical fibres are like nerves and may sense when an element bends an excessive amount of or turns into broken.’

Improved performance was additionally the intention of Richard Kordass, a design engineer at German automotive firm EDAG, one of many companions within the analysis group. They developed motorcycle handlebars printed with copper wiring and ceramic insulation in-built.

‘The one approach that’s attainable is by additive manufacturing,’ careworn Kordass.

A lot progress has been made that Rita Gomes Bola from the European Welding Federation in Belgium, who additionally labored on MULTI-FUN, believes that the newest advances have basically modified how design engineers work.

‘We are able to now rethink how components are designed in ways in which producers by no means even dreamt of,’ she stated.

Aiming for the moon

The probabilities of 3D printing lengthen to the creation of high-performance components for the area business. The researchers created a particular casing for a motor used on area satellites. Its metal physique included copper highways for important enchancment of warmth administration of electrical drives.

‘We doubled the warmth switch price so the electrical motor can now function quicker and never get so heated,’ stated Gradinger, explaining that temperature is a part of what causes metallic components to fatigue.

Broken components can cease working or want restore, which is virtually not possible when a satellite tv for pc is orbiting the Earth. This makes the area business a primary candidate to learn from 3D printing advances.

The EU at present accounts for 22% of the world’s manufacturing output, delivering a commerce surplus in manufactured items of €421 billion every year. Because of this the EU is investing in analysis to additional strengthen this sector.

Additive manufacturing is seen as central to the EU’s manufacturing future and is supported by means of varied initiatives, together with the Made in Europe and Factories of the Future partnerships with business. The intention is to spice up the commercial competitiveness of European firms in areas similar to aerospace, automotive manufacturing and healthcare.

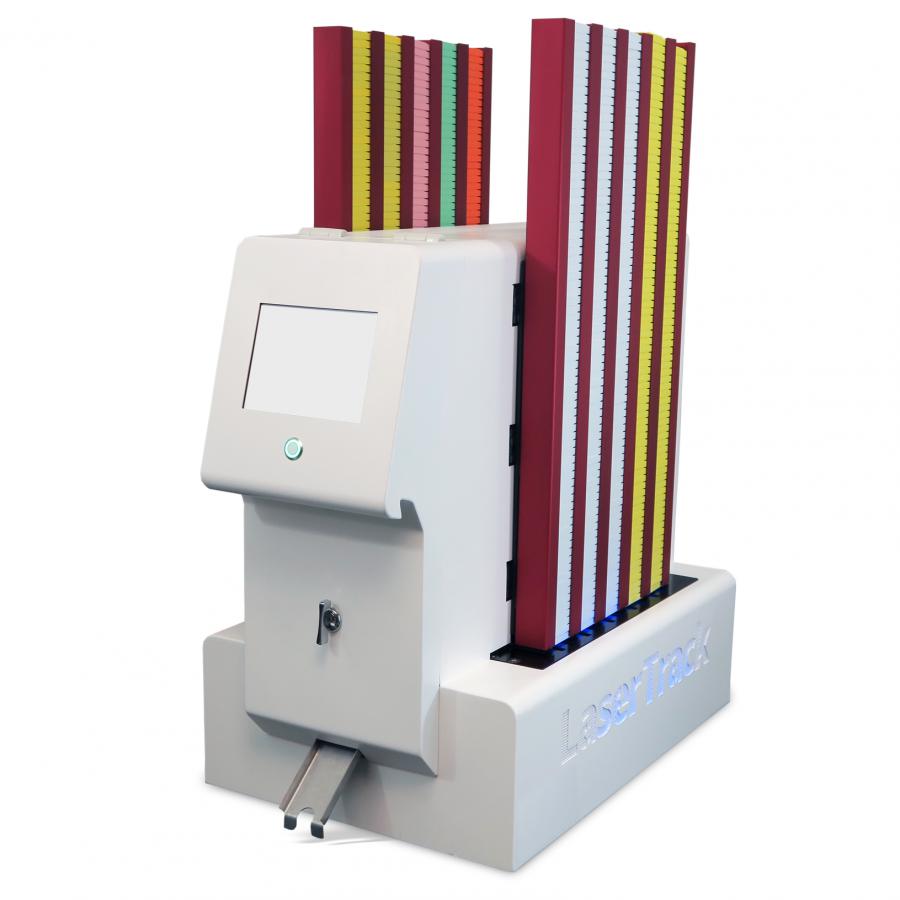

When 3D printing was first launched in manufacturing, it was largely used to create prototypes. Now, nonetheless, it has developed to turn out to be a key a part of the manufacturing course of, making it quicker and extra environment friendly.

‘We’ve moved from fast prototyping to fast manufacture,’ stated Kordass.

3D printed components are already getting used within the aerospace and automotive business the place they assist to scale back gas consumption. Siemens in Germany already 3D prints fuel turbine blades, whereas Airbus makes use of printed components in industrial plane to avoid wasting on weight and gas.

Spreading the phrase

Though additive manufacturing is quickly changing into part of trendy industrial manufacturing, it’s not equally superior throughout all of Europe. Professor Liviu Marsavina, vice rector for analysis on the Politehnica College Timisoara in Romania, is a part of a group of European researchers who’ve been working onerous to unfold 3D printing knowhow extra extensively throughout the EU.

Marsavina, a professor in power of supplies and fracture mechanics, coordinated an EU-funded initiative referred to as SIRAMM that ran from 2019 to 2023.

It related researchers in Romania, with researchers from the Institute of Physics of Supplies on the Czech Academy of Sciences (IPM) in Brno, Czechia, the College of Belgrade in Serbia, the Norwegian College of Science and Know-how and the College of Parma in Italy. Its aim was to create a hub of excellence in additive manufacturing in Japanese Europe.

Educational exchanges helped to create a community that has lasted past the top of the challenge itself.

‘We now have a community during which we all know the place we are able to clear up various kinds of issues,’ stated Marsavina. In the meantime, firms in Romania, Serbia and Czechia are additionally extra conscious of additive manufacturing consultants and tools on their doorstep.

For Marsavina, the fast advance in 3D printing probably raises new points regarding security and safety.

‘Persons are shifting in the direction of utilizing 3D printing to construct not solely small components, but in addition bigger constructions with extra complicated shapes. There’s a must know extra in regards to the properties and reliability of those new constructions,’ he stated.

The analysis group labored on addressing these points by means of real-world analysis, in collaboration with their tutorial companions and business representatives concerned about 3D printing.

The know-how, Marsavina predicts, will unfold to many different industries and even to households.

‘We might someday have a 3D printer in our houses in order that damaged components might be changed by simply printing them your self.’

Analysis on this article was funded by the EU’s Horizon Programme. The views of the interviewees don’t essentially replicate these of the European Fee.This text was initially revealed in Horizon the EU Analysis and Innovation Journal.