This Isn’t Your Grandma’s 3D Printer (Or Is It?)

The emergence of 3D printing applied sciences radically remodeled what is feasible by enabling at-home fabrication of arbitrary designs. What was as soon as the area of business amenities and specialised workshops grew to become accessible to hobbyists, engineers, and inventive minds in their very own houses. With a easy 3D printer and digital design recordsdata, anybody can carry complicated shapes, intricate fashions, or useful elements into existence with little greater than the push of a button.

The recognition of 3D printers has been a significant boon for additive manufacturing generally. Applied sciences have been launched that may do all the pieces from printing a home to medical units. To help the creation of such numerous objects, printing techniques have been created that may work with all kinds of supplies, like plastics, metals, inks, and concrete. However there are nonetheless gaps in what could be produced, even with the various materials choices which might be accessible as we speak.

Some objects made by the machine (📷: Y. Hirose et al.)

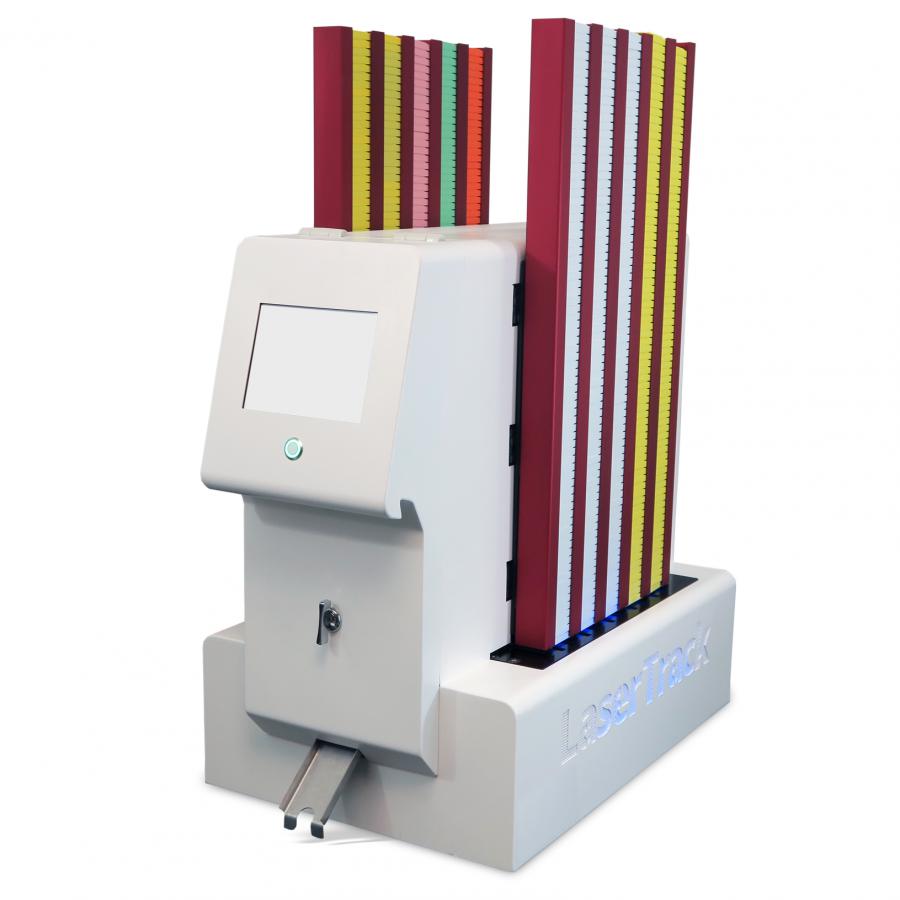

Researchers at Carnegie Mellon College are working to fill a few of these gaps with an modern new method they developed that is known as strong knitting. Quite than producing hole surfaces — as is the case with commonplace knitting methods — strong knitting makes it attainable to create dense, agency, three-dimensional objects made from yarn. To help the fabrication of those objects, the crew additionally developed a strong knitting machine that automates the method very similar to a standard 3D printer.

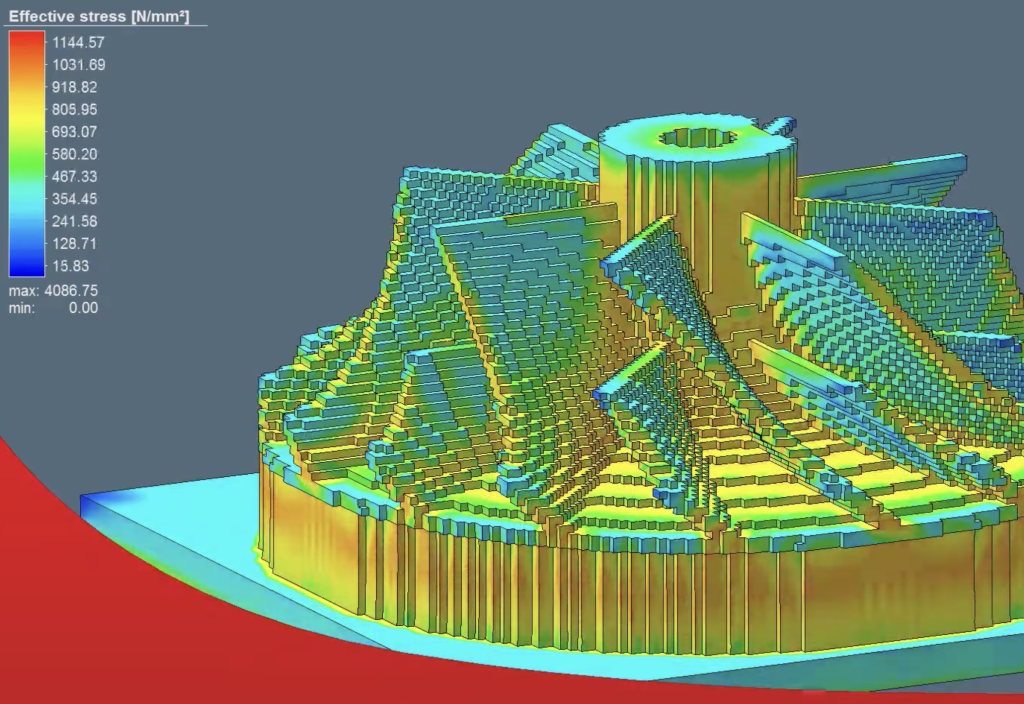

The machine creates strong objects by knitting layers of stitches on high of one another. It makes use of a set of latch needles to create loops of yarn, that are then interlocked to type stitches. The machine additionally has particular hooks known as holders that maintain onto loops from the earlier layer till they’re wanted to type stitches within the subsequent layer. This strategy makes it attainable to create strong objects quite than simply materials.

To program the machine, a sequence of directions analogous to G-code, known as strong knitout directions, are used. These directions are produced utilizing a visible design instrument that was developed by the researchers. Utilizing this instrument, objects could be created by connecting blocks, known as augmented sew volumes, that specify legitimate sew patterns that may be made utilizing the strong knitting machine.

The crew envisions their know-how finally getting used to create all kinds of on a regular basis objects, like sneakers or furnishings. Nevertheless, the demonstrations supplied all consisted of a lot less complicated shapes, like small cubes, prisms, and pyramids. However most of them additionally form of resemble a tangled mess of Christmas lights that didn’t get put away with a lot care the earlier 12 months.

There are some fascinating issues about this know-how, like the power to simply disassemble the objects and utterly recycle the fabric. However it stays to be seen if it’ll in the end discover a useful use case, or simply delight grandmothers that need to make much more unidentifiable knitted objects as presents for his or her grandchildren.