Handddle extends its 3D-printing capabilities after renewing partnership with French Air and Space Force

Handddle, an innovative French startup that specializes in 3D-printing production lines (also known as 3D printer farms by the industry) has renewed their ongoing collaboration with French Air and Space Force. The aim is to expand French forces’ ability to deal with unforeseen circumstances and quickly adapt to new situations on the ground.

This collaboration marks part of the firm’s continued efforts to support the growth of Additive Manufacturing within the defense sector, and meet the French military’s growing production needs.

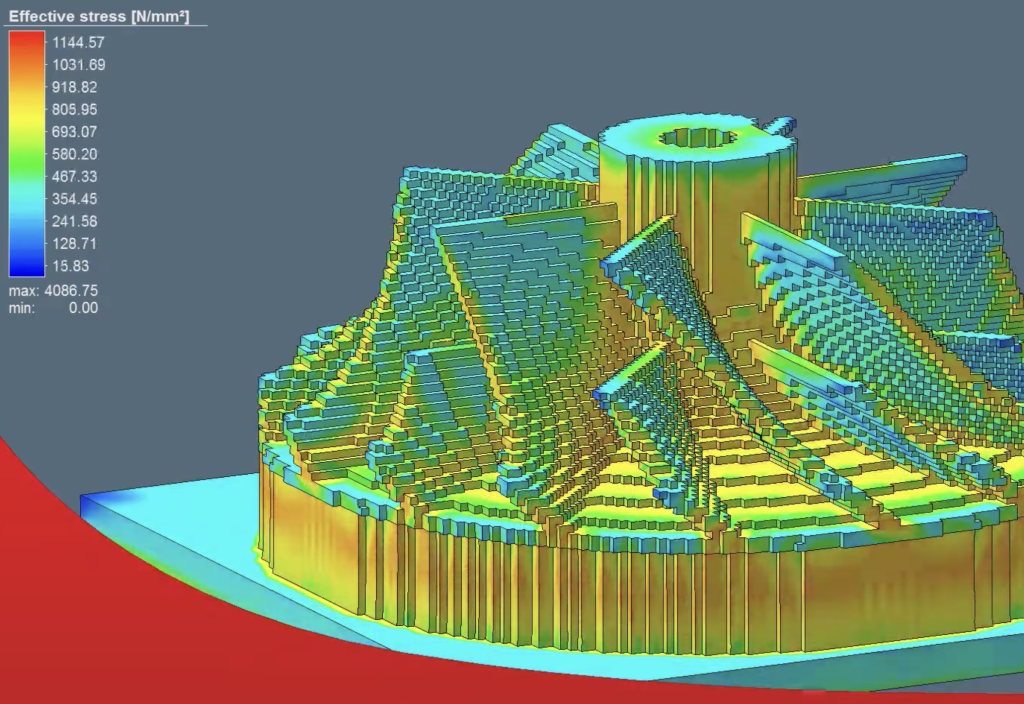

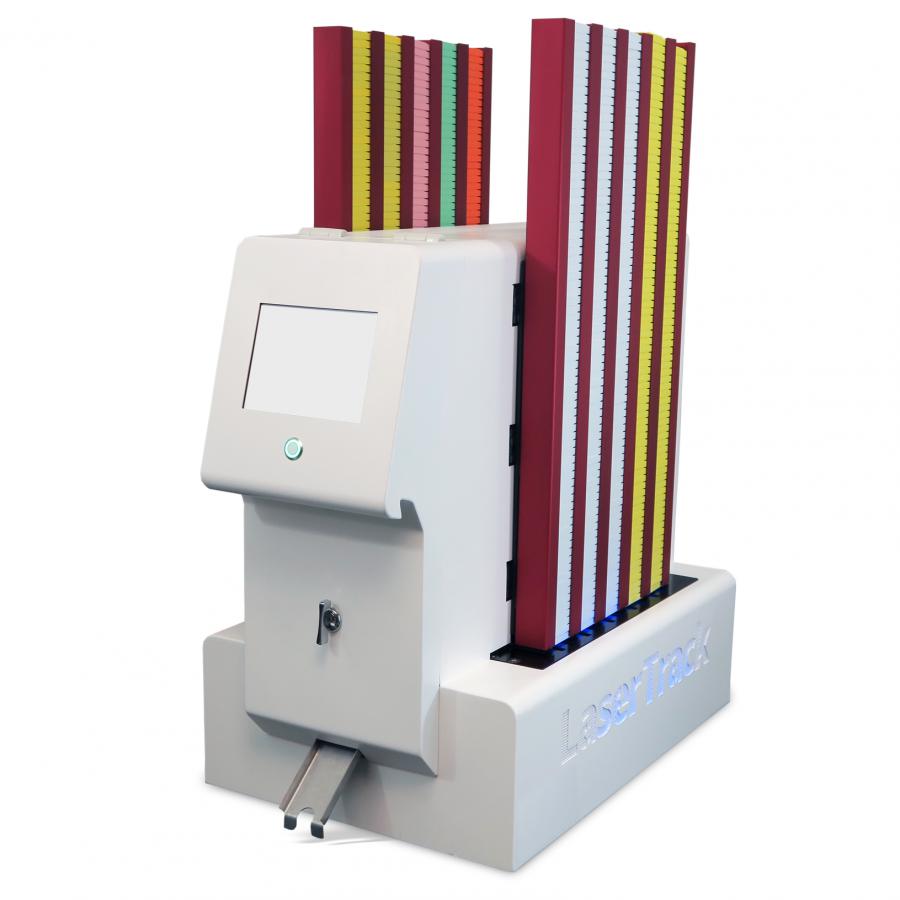

Having installed the first of its Smart Farm micro factories within the French Air and Space Force’s National 3D Printing Pole (PNI3D) last year, the startup is now set to add two new installations. These micro-factories offer the best conditions for 3D printers, as well as software that allows complete control of the printer fleet.

These facilities allow military organizations to quickly meet production goals and produce components that adhere to strict quality, conformity and safety requirements.

“With the possibilities offered by our platform during production phases, we can help them automate workflow tasks related to the management and security of production environments, allowing soldiers to focus on their main mission,” commented Handddle co-founder Dylan Taleb.

Smart Farms and Defense Optimization

French military are keen to use 3D-printing as a key technology in the defense sector.

Incorporating several desktop FFF 3D printers from OEM’s such as Markforged and Ultimnaker, Handddle’s first PNI3D Smart Farm marked the beginning of the company’s defense industry collaborations. Since its installation in April last year, Handddle and the French armed forces have built a robust and ergonomic process for the production of parts that meet the French Air and Space Forces’s stringent industrial standards.

The startup has analyzed data and collected user feedback to improve and develop their product. The two new installations are equipped with improved hardware and a software package, and many workflows have become increasingly automated.

Multi-site testing has also demonstrated an ability to remotely control and supervise distribution production, further optimizing the French Air and Space Force’s production process. Handddle also investigates retrofitting capability, in order to upgrade its original Smart Farm Micro-factory with these latest developments.

Handddle plans to continue expanding its Smart Farm deployment to increase the French Air and Space Force’s capability to be independent, to manage logistics and to sustain and replenish the French Air and Space Force during times of crisis. Moreover, expanding the Smart Farm would also improve the French military’s adaptability on the ground.

The creation of a global Smart Farm network will improve both the availability of technical support and control over costs, which are crucial to armed forces deployed worldwide.

Defense industry and 3D printing

It is not a new phenomenon to collaborate between 3D printing firms and national defense forces.

For instance, last month it was announced that Italian defense contractor Leonardo had collaborated with SFM Technology and large-format 3D printer manufacturer BigRep to 3D print key components for the Royal Navy’s AugustaWestland AW101 helicopters. Leonardo, tasked to develop and manufacture a main rotor blade starting cradle for the Royal Navy, used additive technology. This led to the production of the first 3D printed helicopter cradle.

Philips and the US Navy collaborated to install Additive Hybrid 3D metal printing technology aboard their ships in January this year. This technology, powered by Meltio and Haas metal 3D printers, was installed on the USS Bataan to increase the ship’s self-sufficiency while in operation. At the time, Rear Admiral Brendan McLane, the US Naval Surface Forces Commander, stated that “the introduction of additive manufacturing into naval operations supports readiness and self-sufficiency.”

Subscribe to our Newsletter 3D Printing Industry Newsletter Follow us on Facebook and Twitter to keep up with all the latest 3D Printing news. Follow us on Twitter. TwitterLike our Facebook Subscribe to our page and receive updates 3D Printing Industry Youtube Channel to access exclusive content.

You can find out more about the industry by visiting their website. You can visit the website to learn more about additive manufacturing. 3D Printing Jobs View a variety of roles available and start your career.

The featured image is the Handddle PNI3D smart farm. Photo via Handddle.