Formlabs Introduces the TPU 90A Powder, First Elastomer Material For Fuse Series 3D Printers

TPU 90A powder is durable and skin-safe for many industries including engineering, healthcare, manufacturing, consumer goods, and manufacturing.

Somerville, MA, Mar. 03, 2023 – Formlabs, the leading 3D printing company, is excited to announce its newest material for Fuse Series printers: TPU 90A Powder, a tough elastomer powder. This new material is skin-safe, strong, and functional. It also has high tear strength, elongation, and tear strength.

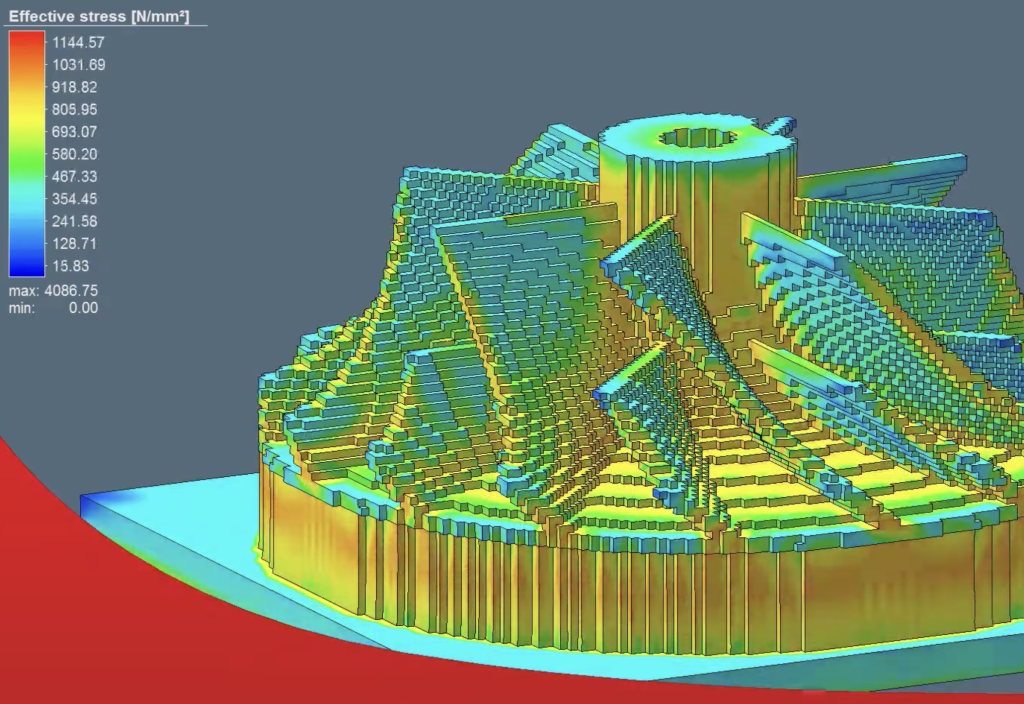

TPU 90A’s strength, flexibility and versatility allow for the production of fully functional components in-house. This gives designers complete freedom and allows for seamless workflows on the Fuse Series SLS3D printing ecosystem. This material allows engineers and manufacturers to bridge the gap between manufacturing steps, produce fully functional prototypes as well as manufacturing aids and end use parts, and have full control over their supply chains. TPU 90A Powder can also be used to create soft touch components, such as grippers, padding, or cushions.

This high performance material is also approved for skin contact. This makes it suitable for medical applications, such as orthotics, prosthetics and other patient-specific devices. TPU 90A Powder’s softness and flexibility ensures optimal comfort and performance, improving outcomes in patient care and streamlining the medical device manufacturing process.

“At Formlabs, we are committed to empowering our customers to truly make anything, from medical parts to wearables,” said Dávid Lakatos, Chief Product Officer at Formlabs. TPU 90A Powder is now available. This material expands 3D printing’s capabilities across many industries. It allows users to make flexible parts that are skin-safe and can be customized to specific applications.

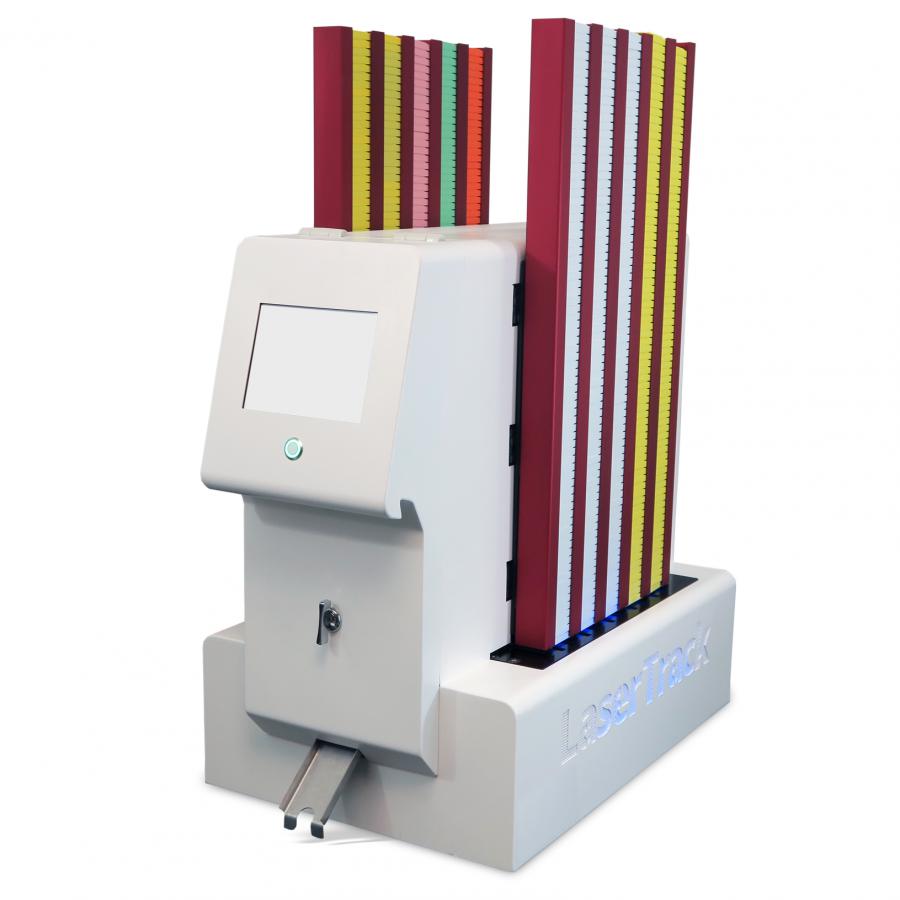

Formlabs’ growing library of SLS materials enables its customers to create parts with a range of properties including stiffness, softness, ductility, and thermal stability. The industry-leading features of the SLS printing process include:

-

Strong and functional TPU parts have high tear strength and elongation at break 110-31%0%

-

Low cost per piece for low volume 3D printed flexible parts

-

It is skin safe and ideal for printing medical accessories and wearable accessories

-

Lower waste and greater efficiency with a refresh of 20%

Formlabs’ TPU 90A Powder is now available for order and will be on display at the Formlabs booth at AMUG 2023 (booth D14). For media assets, click here

About Formlabs

Formlabs has expanded access to digital fabrication so everyone can make it. Formlabs, headquartered in Somerville in Massachusetts, has offices in North Carolina, Japan, China and Singapore. They are the preferred 3D printer for professionals, engineers, manufacturers, and decision-makers around the world. Formlabs products include the Form 3, Form 3B, Form 3L, and Form 3BL powered by an advanced form of stereolithography (SLA) called Low Force Stereolithography (LFS)™ 3D printing, Form Wash and Form Cure post-processing solutions, Fuse 1 SLS 3D printer, and Form Auto manufacturing solution. Formlabs’ Factory Solutions for industrial users gives factories the flexibility and versatility they need to meet the demands of changing industries. Formlabs also creates its own high-performance materials, best-in class 3D printing software, and continues pushing the boundaries of 3D printing. For more information, visit formlabs.com