Innovations and communication technology can transform the industry

Printing United Expo, which was held Oct. 19–21 at the Las Vegas Convention CenterIt is home to one of the most extensive and diverse markets for printing technology. It is also an incubator for new ideas. Consumer-centric supply chains are replacing seasonal development. They eliminate long lead times and follow-up calendars. New digital and software innovations allow for fast tracking, quick reading and immediate reaction to selling and the ability to create garments based upon P.O.s.

“This week has been surreal, seeing the industry come together after such a long time,” said Amanda Kliegl, vice president of public relations for the expo. “The direct-to-garment movement has brought many new customers to the show. Startups who initially began in their garages have grown and now are looking to see what’s available in technology and equipment to buy and build for growth,” Kliegl added.

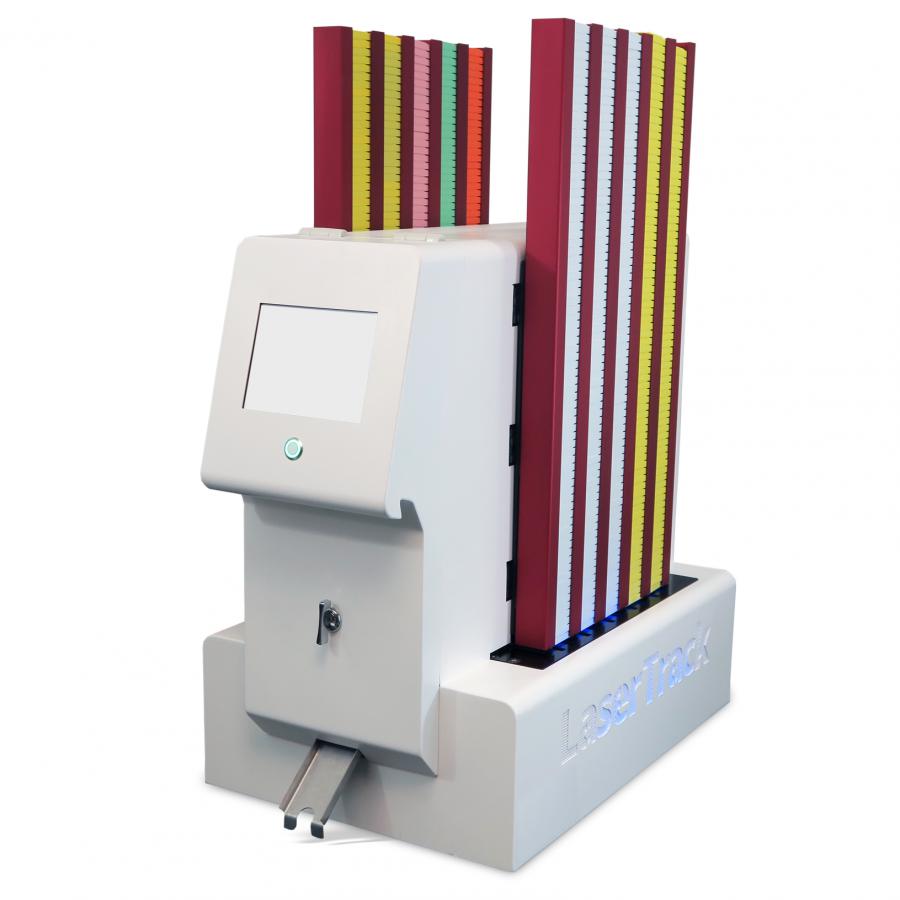

Mimaki Accompanied by strategic partners, the micro-factory was demonstrated Tukatech, Greentex, Beaver Paper, Kieverik Juki. This new generation of production offers same-day designs, which reduce waste, eliminate minimums, and allow for quick turnaround, solving many of the problems previously associated with the manufacturing process. The three-step process of printing, finishing, and assembly allows for products that are ready to sell in hours instead of weeks or months. Victoria Nelson Harris, Mimaki’s senior textile specialist, said, “The micro-factory gives full control of the supply chain with instant production, which is really cool. The complete solution.”

Chris Walia, COO of Tukatech, added, “Technology is so amazing yet underutilized in the apparel industry. We are poised to help companies make the necessary transition by providing cutting-edge product.” One of his goals is to promote micro-factories within the U.S. for speed to market.

At Epson, Six-color printers were introduced, as well as a color-matching system that can read any physical sample and produce the exact color at the touch of a button. Tim Check, senior product manager for textiles, said, “This is another new tool to assist creatives, where their vision comes to life, communicating directly with the printer.”

X-Rite Pantone Software and machinery has been improved to accurately measure specific colors, eliminating the need for color approval. Queenie Bhardwaj, product manager, said, “We are now able to make sure color standards are exact and can be given to our customers by elevating the visual process.”

HP’s innovations in digital printing allow for the elimination and expense of burning screens for small orders. Rolando Martinez, global head of programs and solutions, spoke to improvements in the area of packaging, “Today’s trend is definitely toward smaller runs. Packaging for small industries has never been easier. Low MOQs for testing, fast turns and greater profitability are now achievable.”

Roland The company presented its solution for full-color photo printing using digital dots. Direct-to-garment printers are capable of producing up to 12 pieces per hour. This equipment also includes a heat transfer machine that can be used by entry-level apparel manufacturers. This is a great solution for direct to consumer sellers, such as those who sell with Etsy There are now stores that can produce their goods from home without having to make a large investment.

Los Angeles Apparel I was there to meet screen printers and wholesalers. Pat Honda, president of wholesale, said, “We are reaching everyone who will touch our product before the end user. We’ve seen some customers from as far away as Canada. Connecting in person again has been great.” The company’s stock program of knitwear and accessories is available in custom colors for a 300-piece minimum in seven to 10 days. Its 6½-oz. It is available in 26 colors and costs $6.50.

Gerber Technology It also displayed its customized and on-demand technology at the show. Its ability to photo-image print creates life-like imagery on textiles including cottons with the appearance of jeans.

Omniprint International Daily panels featuring experts to help businesses grow and scale, and to discuss the importance of TikTok Other forms of social media. One panel featured influencers, who shared their experiences building their business and answered audience questions. Chazz Owens (CEO of streetwear brands) was present Twozzday 222 Sports, said, “When I heard about this show, I thought I would check out what’s new and available for growing my brand. I’m looking to expand my line beyond online by collaborating with licenses and will need to be able to present collections and samples more quickly.”

The Kornit Digital Conference was held at the end of the expo’s first day. Ronen Samuel, CEO of Kornit Digital, opened the seminar and passionately spoke about wanting to “be the change” that is long overdue. “After three long years it is a pleasure to be in person,” Samuel said. “We are making fashion better, faster and more personal. In the last three decades, technology has changed so much and we are here for the change. Fashion is one of the last industries to go digital.”

Samuel stated that disruption is essential to addressing change. “There’s been a big e-comm boom, especially during COVID, which has made social media so important to what the consumer is responding to. The ability to produce what is actually sold, never run out of bestsellers and same-day reorders are just some of the customer-first changes,” Samuel explained. “What’s important to Gen Z is sustainability, and the industry is currently the second-biggest polluter. Kornit has made a commitment to tackle this issue and produces an environmental impact report to track these improvements.”

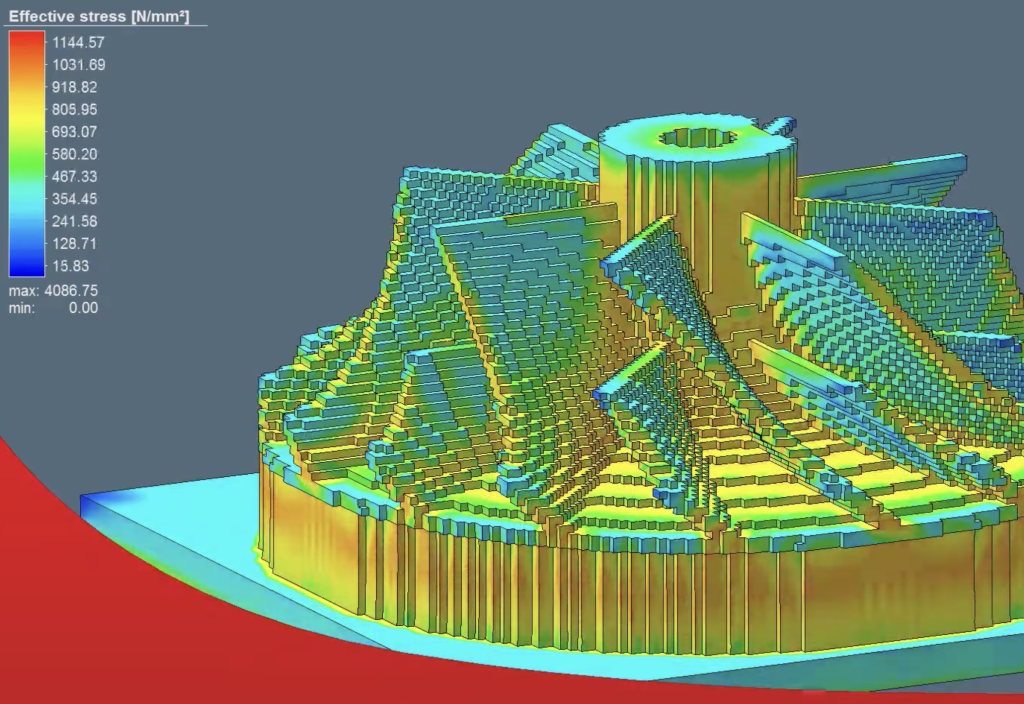

Don Whaley, vice-president of Kornit Digital, discussed the pixel-to–parcel cycle. This allows for rapid product development and closer integration with existing systems. The Max System can print directly to fabric. Coming soon is the Apollo, in which one person can produce 350–400 fully finished garments per hour.

http://www.apparelnews.net/news/2022/oct/27/changing-industry-through-technology-innovations-c/